Upgrading and modernizing batch plants in the glass industry is never an easy feat. Existing installations, machinery, and tight layouts often present significant obstacles that can slow down progress and add to project costs. These challenges are especially evident with traditional rigid piping systems, which usually require time-consuming modifications, costly structural changes, and extensive planning.

But what if there was a better, smarter way to modernize your operations?

Introducing LGT Fluid Hose: the flexible solution

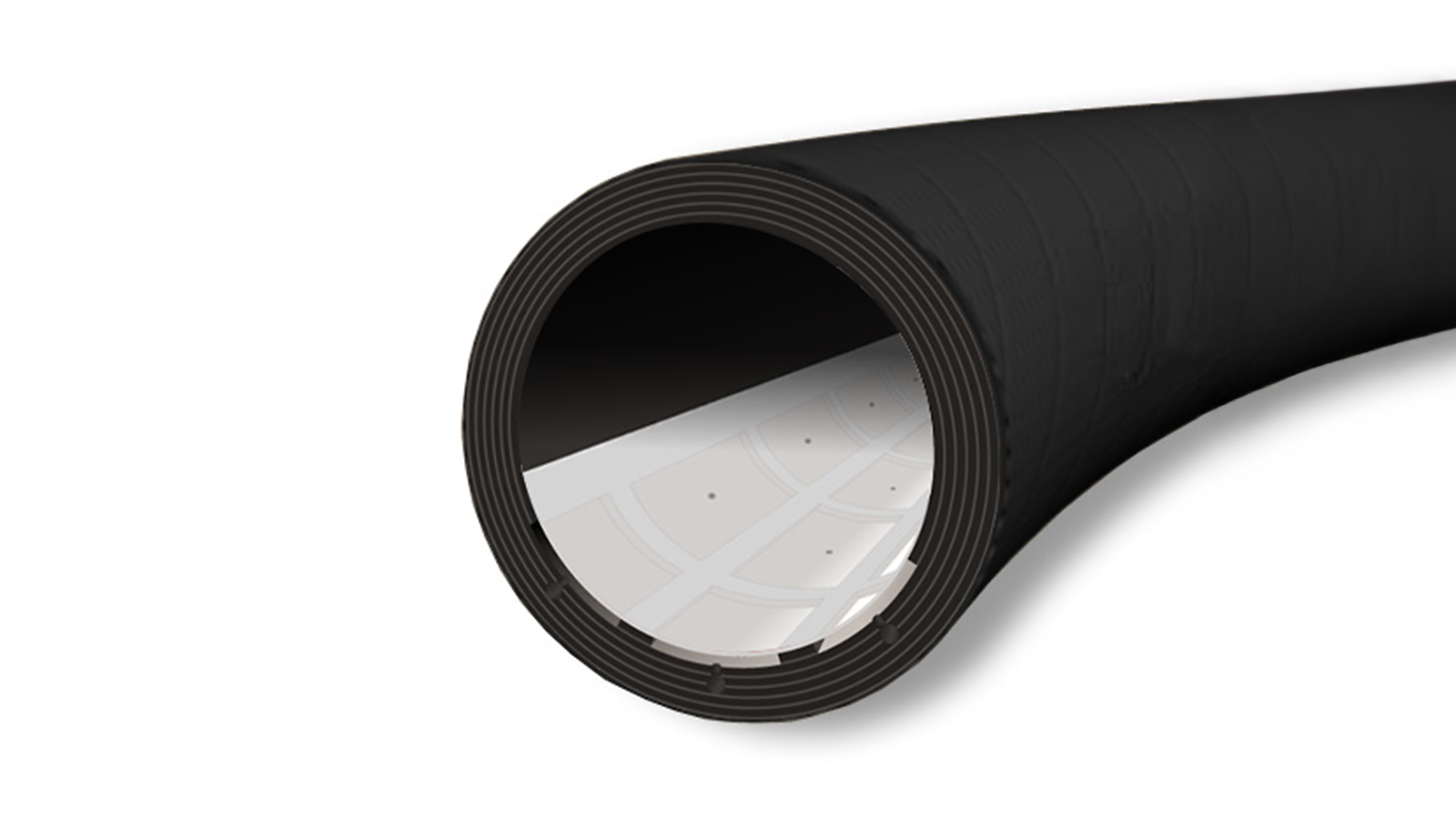

At Lahti Glass Technology we believe that batch plant modernization shouldn’t be complicated. Our innovative hose technology has been tested and proven in real-world applications, making it the ideal alternative to rigid piping systems. Designed with flexibility and adaptability in mind, LGT Fluid Hose effortlessly navigates existing structures and tight spaces – all while reducing downtime and minimizing costs.

LGT Fluid Hose is one of the many solutions we offer through our Solutions Clinic. We help you identify areas for improvement, or if the challenge is already weighing on your mind, just throw it our way and we’ll solve it for you. We know how to solve a wide range of batch plant challenges, and deliver quality, savings, and profit every time.

Unlocking new possibilities

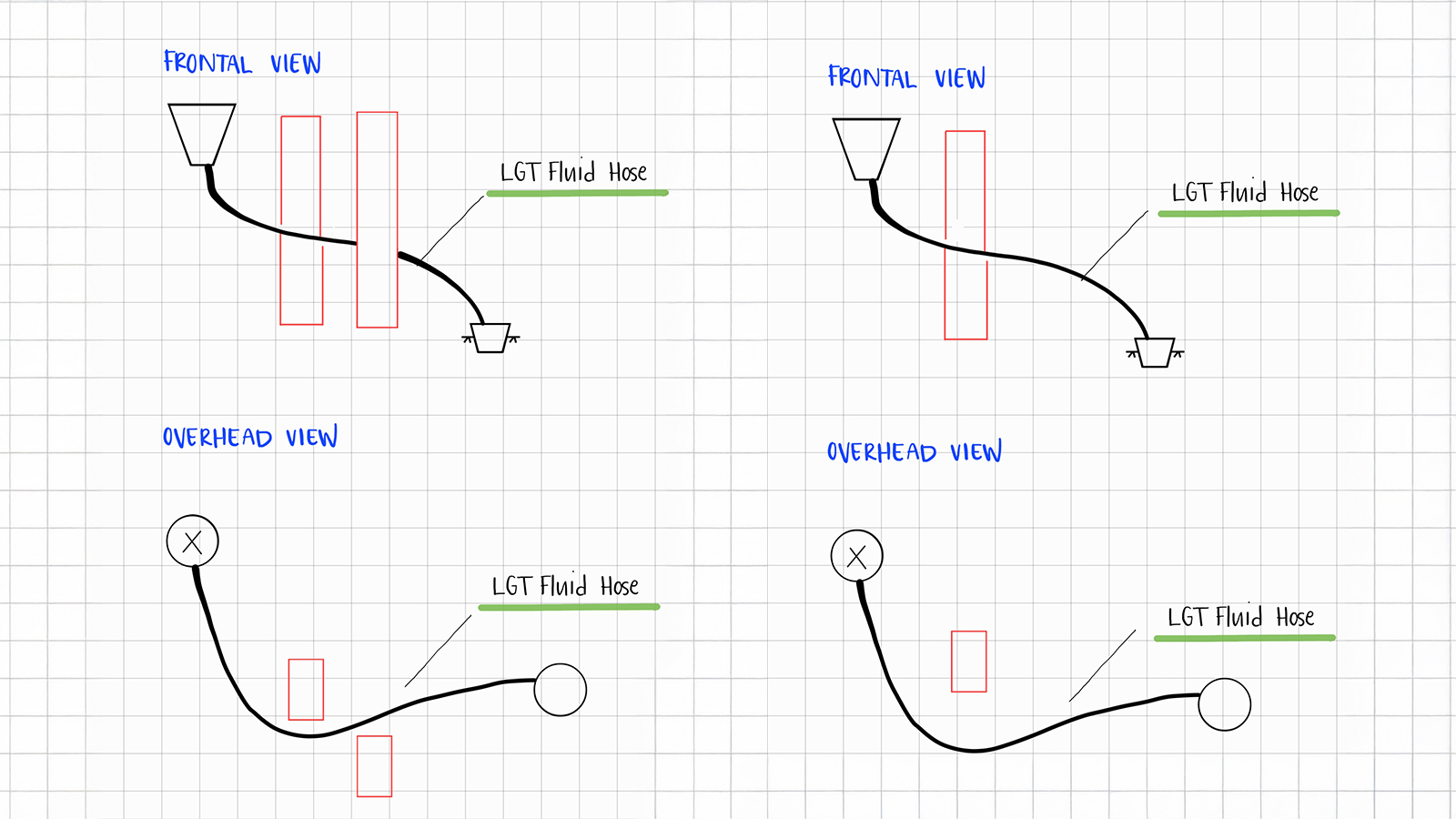

Thanks to its exceptional flexibility, LGT Fluid Hose can reach areas that would otherwise be out of reach with rigid piping. This opens up new opportunities for optimization and innovation – without the limitations of fixed structures. Whether you’re retrofitting an older batch plant or expanding a new line, LGT Fluid Hose helps you achieve your modernization goals seamlessly.

Overcoming obstacles with ease

Unlike rigid pipes, LGT Fluid Hose can bypass machinery, structural poles, and other fixed elements that typically hinder upgrades. This eliminates the need to tear down or rebuild existing structures, making it possible to adapt to even the most complex production layouts.

By removing the need for extensive modifications and structural changes, LGT Fluid Hose also shortens project timelines. Installations are faster, and disruptions to ongoing production are minimized – a practical solution that keeps your operations running smoothly, even during upgrades.

Reducing costs and energy use

Traditional rigid piping systems often require high power and pressure levels to operate efficiently. LGT Fluid Hose, on the other hand, is designed to minimize both energy consumption and installation costs. This translates into significant savings over the system’s lifetime, while also supporting your sustainability goals.

Minimizing maintenance needs

LGT Fluid Hose is engineered to resist clogs and buildup, making it virtually maintenance-free. If replacement is ever needed, it can be done quickly and easily – without the hassle and expense associated with rigid piping maintenance.

Modernizing your production lines doesn’t have to be a complex or costly process. With LGT Fluid Hose, you gain a flexible, efficient solution that adapts to your needs – not the other way around. Say goodbye to unnecessary workarounds and costly rebuilds, and hello to a smarter, simpler approach to batch plant modernization.

At the Solutions Clinic, there’s no challenge we can’t solve. Wondering what kinds of puzzles we’ve already solved? Take a look at some of our Solution Clinic example cases.